Auto Candle Extruder Machine

The fully automatic extruder candle making machine can be made into pillar candles or cylindrical household candles.

The candle strand extruded from the paraffin powder or plates is cut to candle length by rotating knives. Then the head and base form are shaped by a milling machine. Optionally, the candles can be milled conically into taper candles in the taper candle line integrated into the system.

- GAOWAX

- China

- 30~60days

- 50 Sets per Month

- Information

- Video

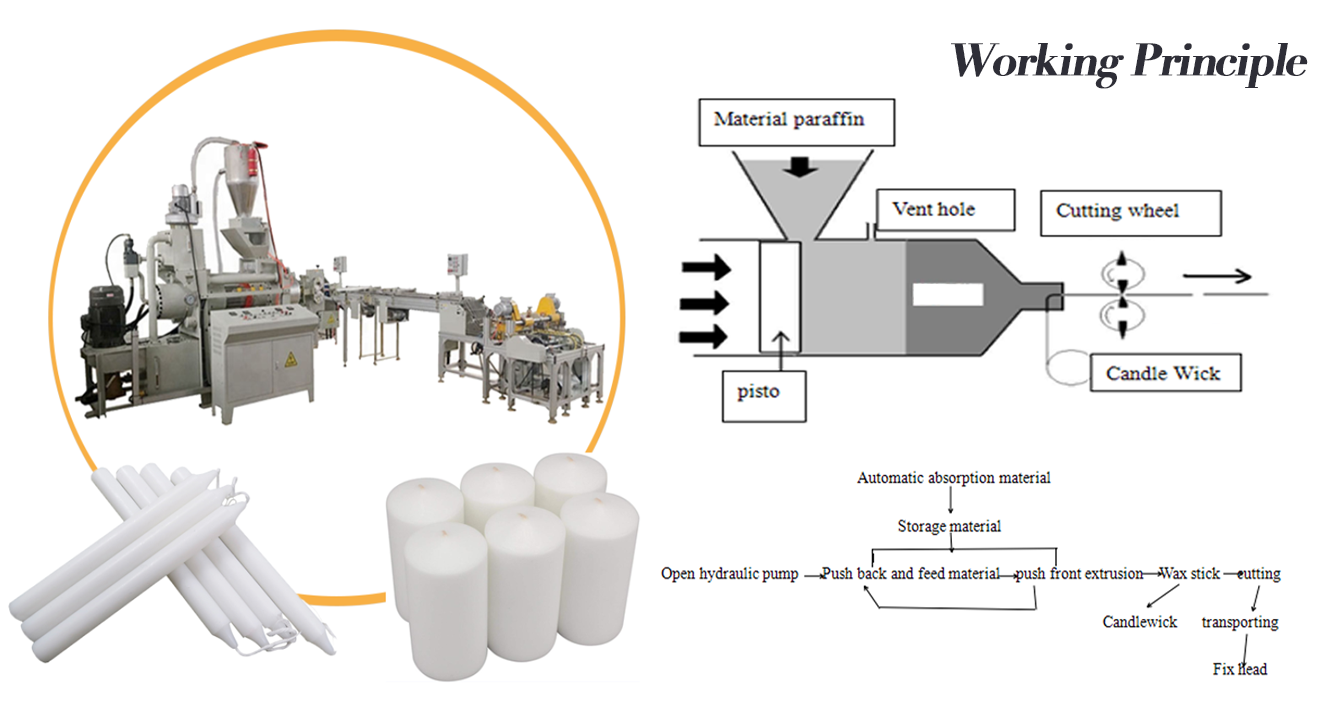

Herrhammer Auto Candle Extruder Machine Operating principle:

When the piston returns, wax powder is injected, and the piston squeezes out the wax strip twice. Wax sticks are cut into wax sticks of required length with a cutting wheel.

Diameters | 12-50 mm |

Lengths | 100-350 mm |

Capacity(single side) | 6000 candles/hour |

Capacity(double side) | 11000 candles/hour |

Main machine power | 22 kw |

Part machine power | 6.8 kw |

Dimensions | 5800×3800×3000(mm) |

Weight | 3800 kgs |

Packaging Details | One 20 ft container is enough for the machine |

Advantage Of Auto Candle Extruder Machine

1)Mitsubishi Programmable Controller (PLC)

2)Taiwan Delta Industrial Inverter

3)Full CNC machining cylinder assembly German seals in the cylinder

4)Hydraulic pressure pump with good quality corrosion resistant plate

Auto Candle Extruder Machine Purpose:

Automatic candle extruder machine uses fully refined or semi-refined paraffin wax particles or wax powder above 56 degrees as raw materials. It can directly extrude straight round rod wax and straight striped rod wax. The shape of the top and tail of the candle can be changed according to needs, and it can also be used for extrusion Φ30-Φ50 large diameter cylindrical wax.

Herrhammer Auto Candle Extruder Machine Features:

1. It can automatically complete a complete production process of feeding, extruding, trimming and outputting.

2. Adopt plunger hydraulic system, PLC instruction programming reciprocating automatic work, frequency conversion control and trimming, the overall equipment operation is stable and reliable.

3. Changing the diameter, length, and head shape of the candle is quick and convenient.

4. The wax core and wax strips are extruded synchronously, which can adjust the elasticity of the wax core to ensure the burning time and stability of the candle.

5. Equipped with output measurement function, you can check output at any time.

Herrhammer Auto Candle Extruder Machine Technical parameters:

1. Production range Straight rod wax, striped wax: Φ12-30mm Length: 100-300mm.

2. Production capacity Φ12-25mm Length: 100-200mm, about 11000 pieces per hour (length exceeds The output decreases gradually when the diameter is above 200mm) *Under the condition of raw material temperature 18℃-25℃, oil temperature 30℃-55℃.

3. Power configuration: main engine power 22kw auxiliary power 6.8kw.

4. Dimensions 5800×7600×3000 (mm).

5. Whole machine weight 4200kg.

Installation and adjustment:

Install

1. The installation site should be spacious and flat, and the ground foundation should be solid.

2. In the process of moving equipment, pay attention to personal and equipment safety.

3. After the equipment is positioned, adjust and fix it horizontally.

4. The hydraulic cooler should be connected to the cold circulating water.

Precautions:

1.This machine is designed to produce rod-shaped candles and is strictly prohibited for other purposes. 2. The temperature of the hydraulic oil should be controlled at 30℃-55℃, and the temperature of the raw material should be controlled at 18℃-25℃, otherwise it will affect the output and reduce the service life of the equipment. 3. It is strictly forbidden to place debris on the control cabinet to prevent rain and splashing. 4. The repair and replacement of electrical parts should be operated by personnel with relevant qualifications when the power is off, and be careful of electric shock. 5. Hydraulic joints may become loose due to hesitating transportation, vibration, thermal expansion and contraction, and the equipment should be checked and tightened one by one after running for a period of time. 6. During the operation of the equipment, it is strictly forbidden to touch any moving parts. During operation, please avoid clothing contact with gears, chains and other parts to avoid being involved in accidents. 7. Clean up waste wax, replace molds, repairs, etc., must be carried out in the shutdown state. 8. The equipment must be operated in an attended state.

The extruder adopts intermittent mode for extrusion operation. The piston squeezes the wax powder into wax strips (with wax core). When the piston returns, wax powder is injected, and the piston squeezes out the wax strip twice. Wax sticks are cut into wax sticks of required length with a cutting wheel.

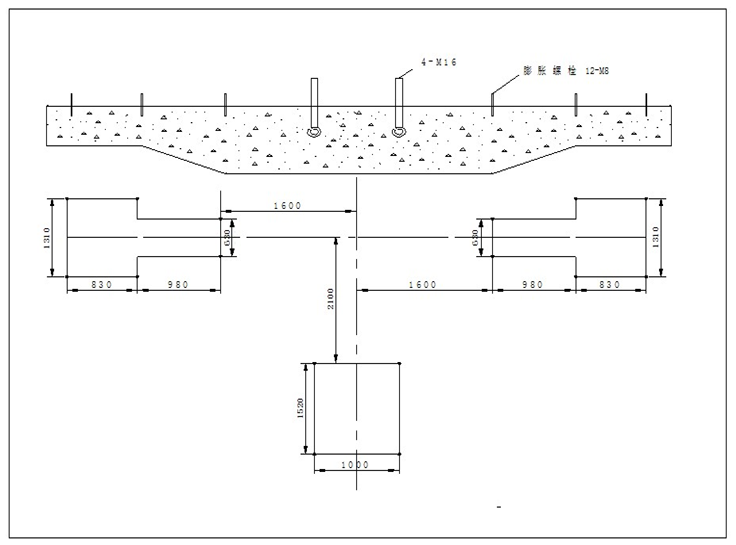

Foundation drawing: