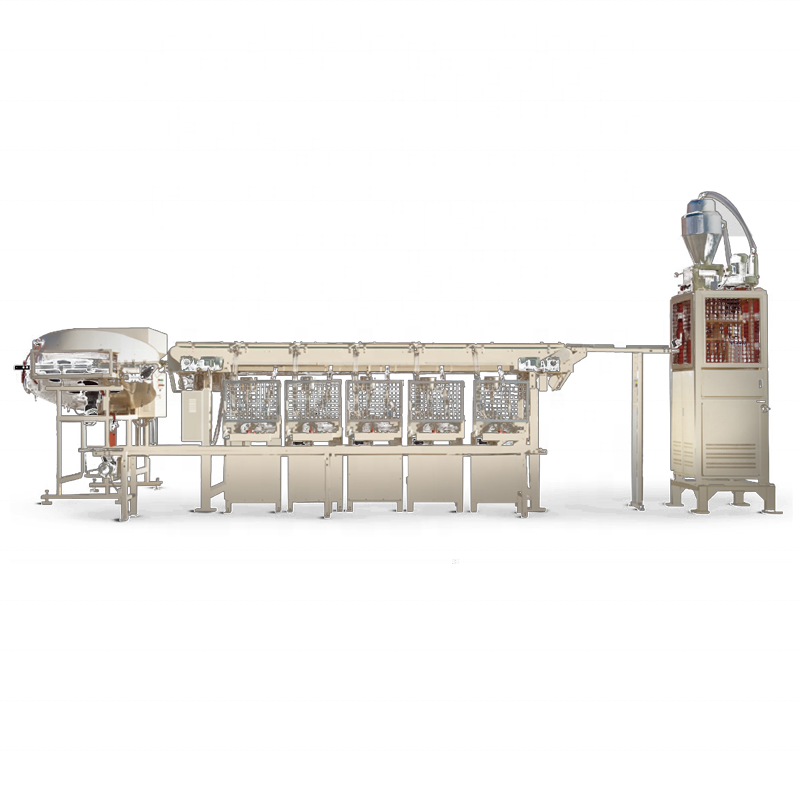

Auto Tealight Production Line

The automatic tealight production line of candel machine is made up of automatic wicking & pressing in section, wax conveying section,tealight holder conveying section and finished products conveying section. The production line realizes automatically producing,high-efficiency and quality.This machine design absorbs advantage of home and aboroad, combines actually using condition in candle factory, in order to make it mostly reaching customer's require.

- GAOWAX

- China

- 15~30days

- 50 Sets per Month

- Information

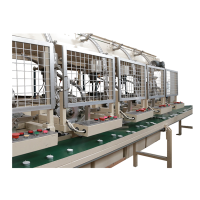

This auto tealight production line is used to assemble semi finished products like tealight cake, aluminum cup, wick sustainer and candle wick together. It is made up of 4 wicking and assembling workstations, 1 set of aluminium cup and tealight cake back and forth conveyor, and 1 final production conveyor.

Adopt VFD to adjust working speed, and PLC program control.

With detecting device, when no tealight cake, wick fold, no sustainer, no cup, any issues of these happen, the corresponding workstation will stop automatically, meantime LED light will shine to show the reason, operator will know and can do necessary maintenance, save time.

Tealight candle making machine design absorbs advantage of in and abroad, combines actually using condition in candle factories, in order to make it mostly reaching customer's require.

The line are made up of 1 set of Automatic Rotating Tealight Machineor 1 set of Auto Tealight Production Line, 5-7 sets of AutomaticAluminum Cup Loading Machines,1 set of aluminum cup sorting machine, 1 set of aluminum cup round trip convevor belt, 1 set of tealight round trip convevor belt.1set ofproducts convevor belt.

Auto tealight production line is reasonable in the desin with high manufacture precisiorIt is also integrated with the advanced electronic control system, which allows thefree control of all machines of the production line. lt is convenient in the operation.

The production line realizes the automatic production by the integration of electronitechnology and machinery,which can save lots of manpower.

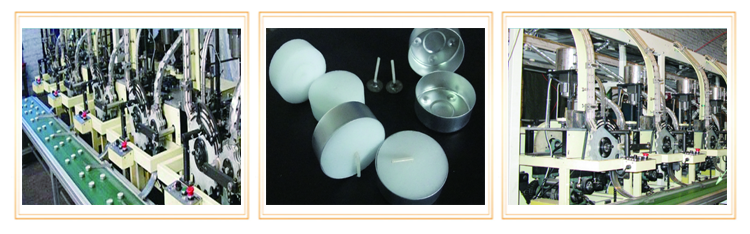

Candle Diameter | 37mm |

Candle Height | 12-14mm |

Capacity | 35000pcs/hour |

Automatic Wax Powder Loading Device | With Automatic Wax Powder Loading Device |

Total Line Weight | 3000kg |

Outline Dimension | 8000*2000*2900mm |

| Power Supply | 9KW |

Application: Using paraffin wax powder as material for pressing tealightcandles (The products pressed out with wick and wick holder together, aprocesses are finished automatically).

Automatic Rotating Tealight Candle Machine is our patent desianed machineFrom loading wax powder, pressing to products, the whole processes will befinished automatically.

Tealight weight and height can be adiusted in a certain range bv hand wheel.

Our designer refines every detail of the equipment according to the customer demands.Matching the upper/lower punches with the cavity accurately.

At the speed of 35000pcs/hour for pressing tealight, there is a center hole inside the candle to allow for the candle wick, after loading the aluminum cups can be packed.

It can also be connected with our assembly line of tealight candle filling, which can greatly reduce the number of operators, it greatly saves the cost and reduces the forming time.