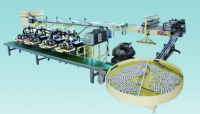

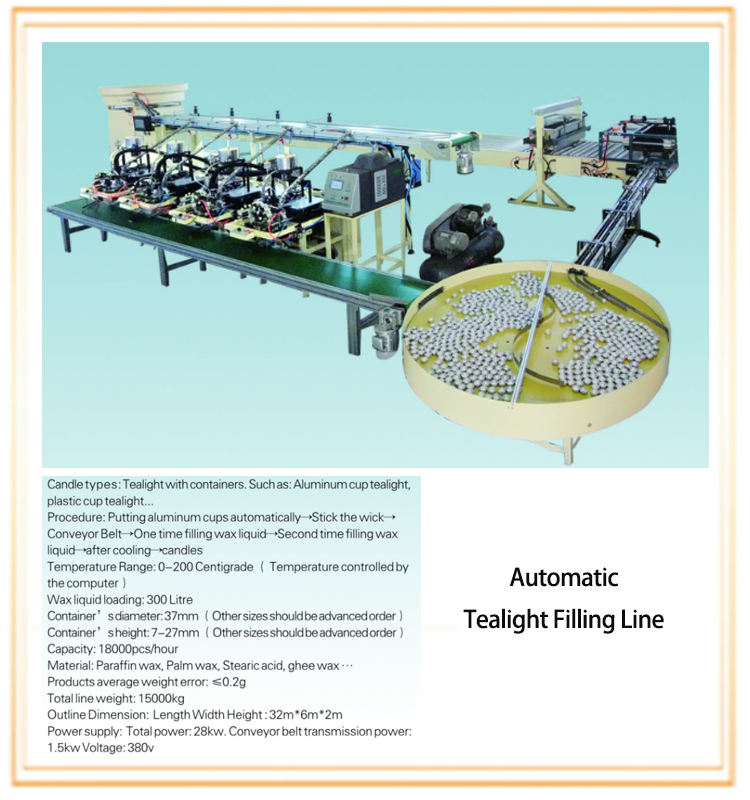

Automatic Tealight Filling Line

The auto tealight production line of tealight candle machine is made up of automatic wicking & pressing in section, wax conveying section,tealight holder conveying section and finished products conveying section. The production line realizes automatically producing,high-efficiency and quality.This tealight candle making machine design absorbs advantage of home and aboroad, combines actually using condition in candle factory, in order to make it mostly reaching customer's require.

- GAOWAX

- China

- 15~30days

- 50 Sets per Month

- Information

Automatic tealight candle filling assembly line is independently developed which is a fully automation and machinerassemblv line. Whole process is implementing with highly mechanized and speed connectiofrom sorting tea-light cup, loading tea-light wick sustainer to tea-light candle filling, LCtouch screen monitor and non-human factors intervention are ensure to improve production nefficiency.

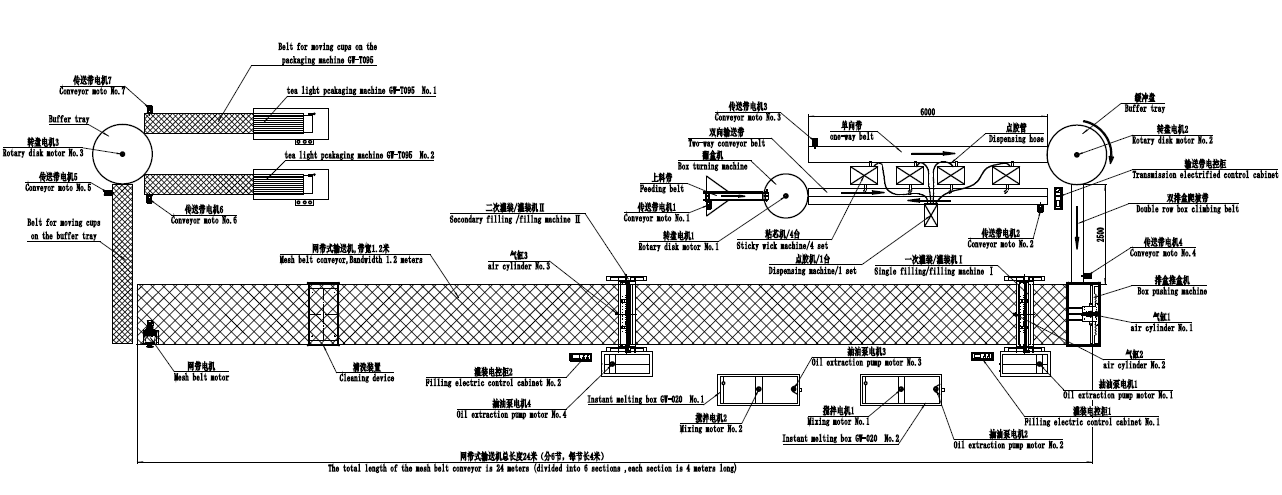

The tealight filling assembly line is combined by four basic parts which are tea-light cup sorting unit, tea-light cup loading unit, tea-light cup storage & pushing unit and wax melting & filling unit.

Stainless steel conveyor belt, stainless steel spiral heating pipe and accurate adjustment filling system are our assembly line characters.

Highly mechanized and speed connection will guarantee to produce 18000 pieces per hour.

Auto Tealight Candle Making Machine Application: Production line of jar candle: it is suitable for the wax filling in all kinds of containers. It is flexible and convenient in the operation, while the direct-view digital display device is more convenient for adjusting the filling temperature and time. It has been widely adopted by candle enterprises. It can also be improved and customized according to the customer requirements.

It is used for the candle filling that uses the melted candle solutions as the raw materials in the containers. The filling line with different sizes can be customized according to the customer requirements, for instance the mesh belt with the length 40m and width 1.3m.

The tealight candle making machine is mainly for filling candles. The production line of candle filling consists of container pushing device, candle drippings sprayer. filling box, conveyor mesh belt, wax-melting box and smoothing box.

It is suitable for the candle filling in the containers with the diameter less than 110mm and height less than 250mm. The tealight candle making machine includes the automatic and manual controls. It is flexible and convenient in the operation, while the direct-view digital display device is more convenient for adjusting the filling temperature and time.

It has been widely adopted by candle enterprises. It can also be improved and customized according to the customer requirements. The speed of conveyor mesh belt is controlled by the variable frequency drive, which can be adjusted according to the wax cooling time and yield. The filling time is controlled by the photoelectricity to fill the candle with different volumes; PLC controls the transmission speed and filling time of the mesh belt, which is displayed on the screen.