Immersion Pillar Candle Making Machine

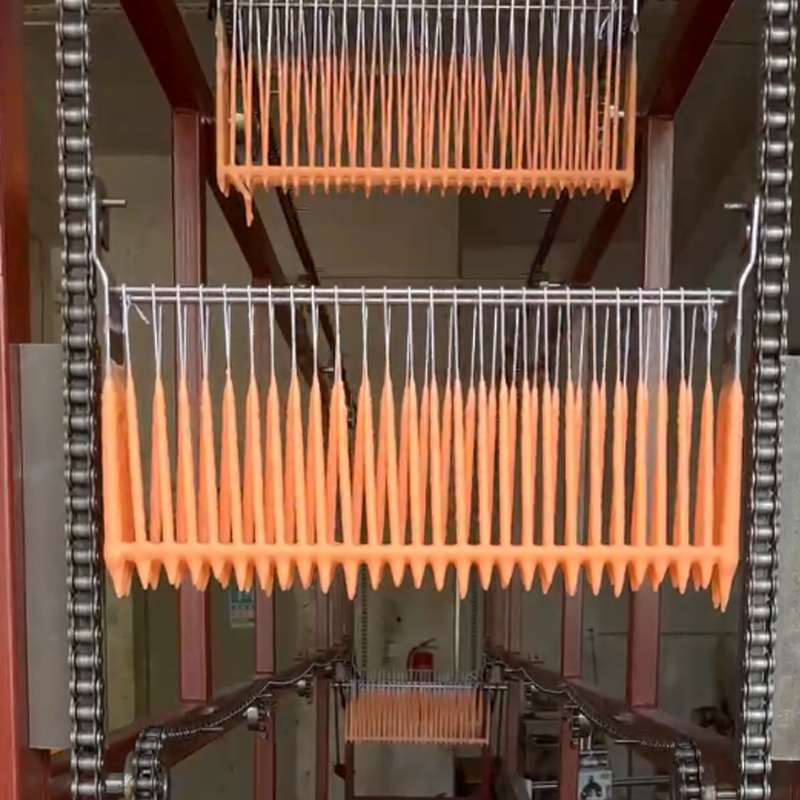

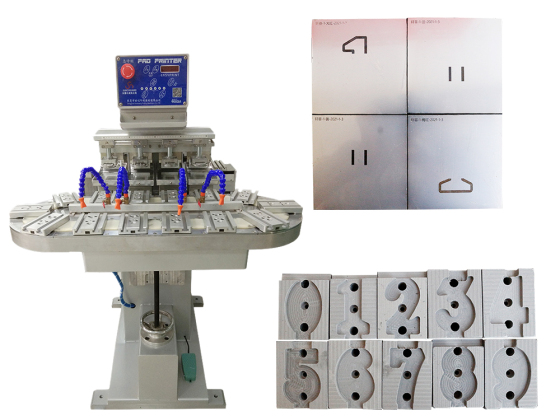

The auto pillar candle machine is immersed in wax water for many times through the wax thread to reach the desired diameter. Each time it is soaked, the diameter of the candle increases by about 0.5mm. One machine can produce candles of various specifications. The length of the candle is controlled by the mold. The machine is combined with labor, which is convenient to operate and simple to use.

- GAOWAX

- China

- 15~30days

- 10 Sets per Month

- Information

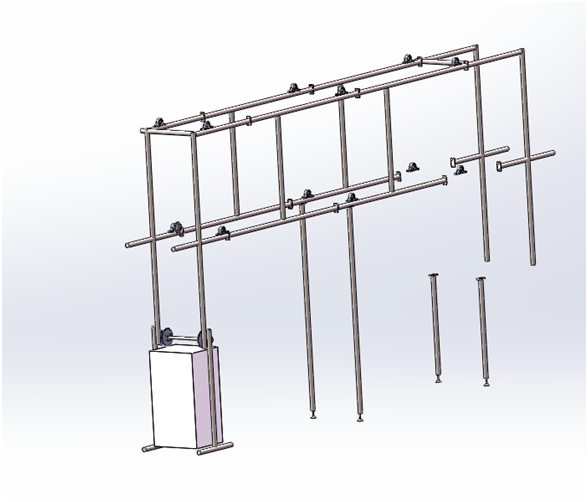

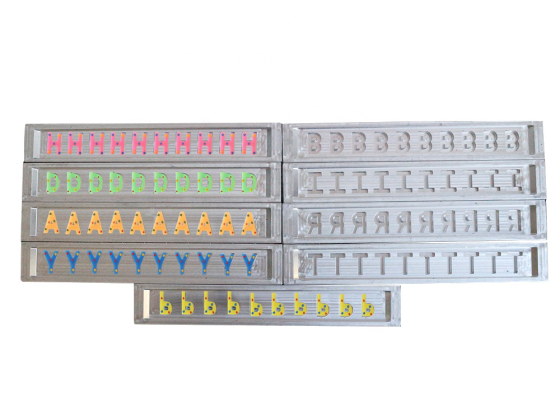

Immersion Pillar Candle Making Machine Parameter:

Production host Frame size: length 3 meters, width 0.6 meters, height 3 meters Wax melting pot: capacity 100 kg, power 6kw motor: 1.1kw adjustable speed, including 20 mold.

Wax melting tank:

start to melt wax. The temperature of wax water is set at about 80 °. The higher the temperature is, the smaller the diameter added each time.

Hydraulic Pillar Candle Machine Installation instructions:

1: Place the winding machine, and choose a suitable factory location to place the winding machine.

2: Install the frame and arrange the frame. Note: The total height of the machine is 3 meters, and a 3-meter-high site should be used in the factory for candle equipment.

3: Place the wax pot. Arrange the relevant equipment.

Other specific installation details: a video will be recorded for actual installation and use, and online after-sales service will be provided.

Immersion Pillar Candle Making Machine Foundation drawing: