Manual Strip Candle Making Machine

It is a customizd manual stripcandle making machine, candle size, shape and moulds quantity can be designed according to customer's require, to make tealight candle, dinner candle, taper candle, pillar candle, wax ring and so on.

- GAOWAX

- China

- 15~30days

- 50 Sets per Month

- Information

- Video

Manual Candle Making Machine Product Description:

1.The manual strip candle making machine is made from fine stretching seamless copper tube and lead alloy, etc, through finishing machining, the machine crown bar adopts seamless steel pipeline, which can be adjusted up and down to change candle length.

2.Main products : lighting candle machine, birthday candle machine, cup candle machine, cylindrical candle machine, cone candle machine, tea wax machine, Buddhist candle machine, craft candle machine, craft candle mold, spiral candle machine. the moulds customized .we can manufacture machines according to customers provided candle samples and drawings.

Candle weight (g) |

Diameters Length(mm) | Time/hours | Machine size (mm) | Machine weight (kg) |

30-90 | Φ18-Φ24, H152-305 | 4-6 | 1050-1200*480-550*850-880 | 124-195 |

12.5-113.4 | Φ13-Φ24.5, H65-367 | 2-5 | 1200*330-580*850-980 | 150 |

175 | ||||

20-70 | Φ18-Φ24, H152-305 | 4-6 | 1150*360-520*900-960 | 140-225 |

The connect of the Manual Candle Making Machine :

The strip candle making machine is transported as a complete machine, no additional steps are required for installation. The machine needs to remove the outer wooden packaging and place it in a suitable place in the factory. It is recommended to be closer to the waxing device.

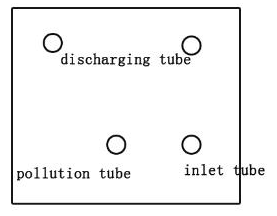

The machine needs to be connected to the water tank, just install the cooling water as shown in the figure below. In order to achieve the cooling water to quickly cool down the candle, to achieve a higher production efficiency.

The operating of the Manual Candle Making Machine :

1. Put the machine flat on the ground. Put oil in each mould (for lubrication, apply oil after waxing several times on the mould). Play a mold lubrication effect.

2. Thread the wax thread. The wax thread needs to be threaded and placed on the machine before the machine works. After the wax thread passes through the spool once until the spool is used up, change to the next spool and repeat the operation steps.

3. Connect the circulating water before the strip candle making machine works. To achieve the effect of cold water circulation cooling, if it is not connected to the circulating water machine, it can also be used, and the production efficiency and candle output rate will be reduced during use.

4. Use a wax-melting pot or a wax-melting device to turn the wax into a liquid, and pour it evenly on the candle machine.

5. Wait for the candle to cool down. Generally, a candle needs to wait for a cooling time of 15-20 minutes, depending on the local temperature and factory temperature, there will be errors.

6. After the candle has cooled down, shake the wheel to remove the wax. After the candle is removed, use a shovel to remove the candle, enter the next pouring, and cycle this step for production.

Remark:

Manual pillar candle making machine is especially suitable for the Beginners. For candle producers who want to produce many kinds of candles, manual candle machines are the first choice too. They are the most common machines for making candles now. Although they are called manual candle making machines, they can provide big output capacity as well. With an investment of less than USD 10,000, a small-scale candle plant can have 3-8 machines which can produce 8,000-30,000 candles per Day (8 working hours). These candles can be in different kinds

and styles. Just 2 or 3 persons can easily handle these manual candle making machine.