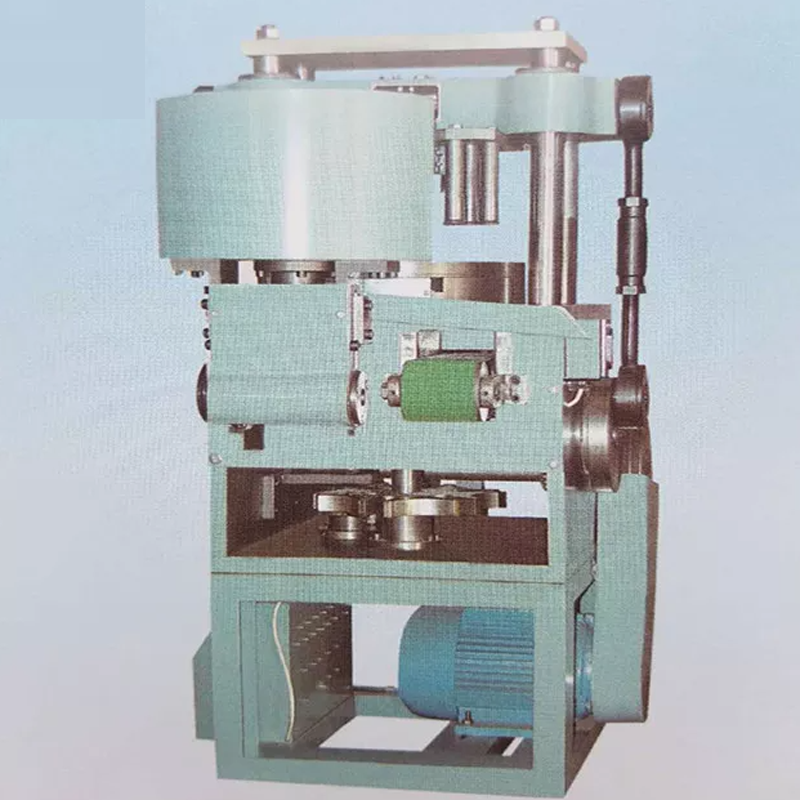

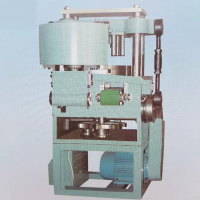

Multi Function Candle Pressing Machine

The multi function candle pressing machine uses wax powder as raw material, equipped with a feeding system, filler, extrusion molding, and output as a whole set of production processes. By replacing part of the mold or the whole set of molds, tealight, small cup candle can be produced. The produced candles have stable weight and transparent thread holes.

- GAOWAX

- China

- 15~30days

- 50 Sets per Month

- Information

With reverse pressing function, according to the customer's require, only to change cavities and other moulds can get different types of pillar candles, following loading material, the whole process will be completed from pressing to material returning automatically.

Working Procedure: Loading wax powder into hopper, with the candle extruder machine rotating, wax powder flowing into the cavity, the upper and lower punches press the up and down ends of the cavity at the same time. The candles pressed out with a center hole inside the candle to allow for the candle wick and pushed to the conveyor belt by the material tamping rod, the process finished.

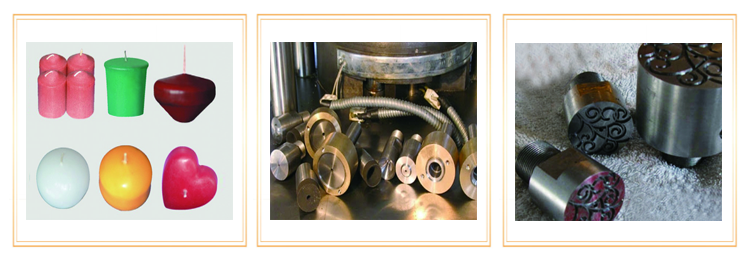

Both upper and lower punches have heating section, saucer with heating belt. So candle's surface smooth, if the upper punch with carved patterns, the pillar candles pressed out with carved patterns.

Changing moulds will get different types and sizes of candles, we constantly provide different types of moulds for customer's require, sending me candle samples, we supply moulds to u, also supply candle extruder machine parts for long-term.

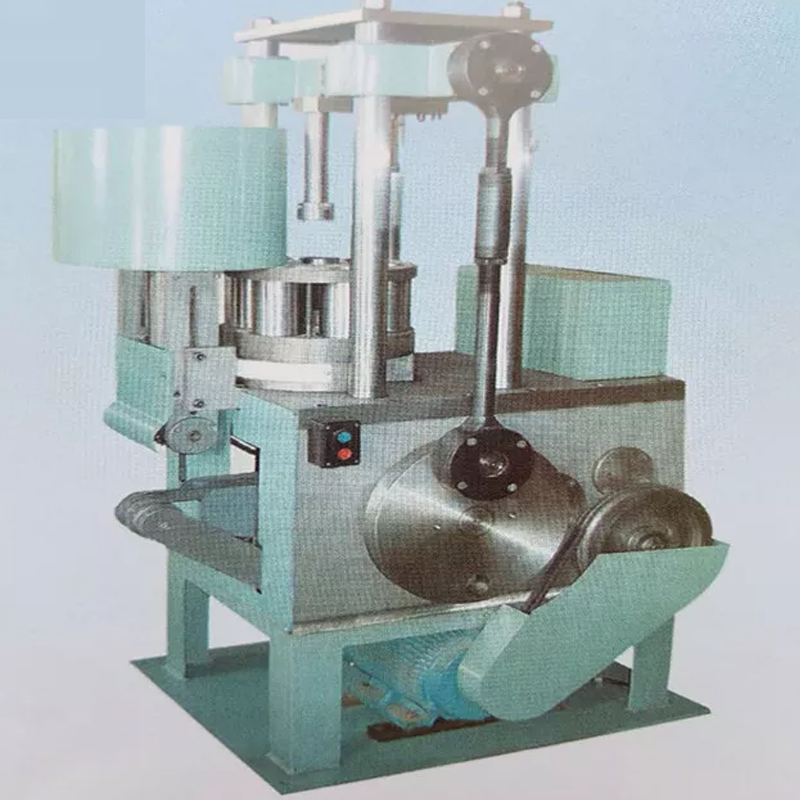

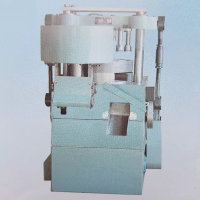

Multi-function 2 - 4 Pillar Candle Machine with reverse pressing function, according to the customer's reuquire, only to change cavities and other moulds can get different types of pillar candles, following loading material, the whole process will be completed from pressing to material returning automatically.

Working Procedure: Loading wax powder into hopper, with the machine rotating, wax powder flowing into the cavity, the upper and lower punches press the up and down ends of the cavity at the same time. The candles pressed out with a center hole inside the candle to allow for the candle wick and pushed to the conveyor belt by the material tamping rod, the process finished.

Both upper and lower punches have heating section, saucer with heating belt. So candles surface smooth, if the upper punch with carved patterns, the pillar candles pressed out with carved patterns.

Changing moulds will get different types and sizes of candles, we constantly provide different types of moulds for customer's require, sending me candle samples, we supply moulds to u, also supply machine parts for long-term.

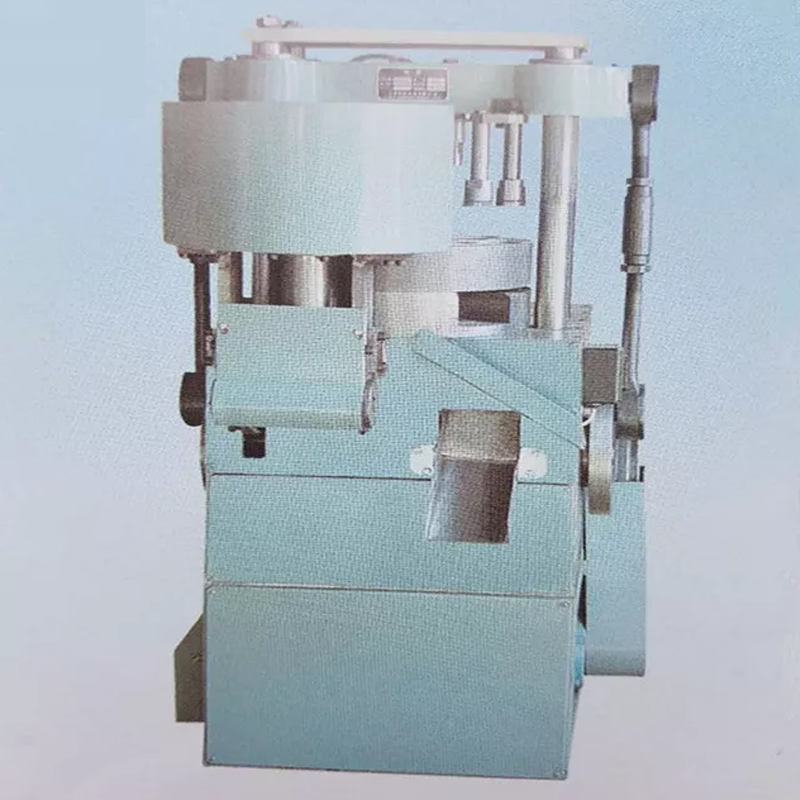

According to the customer's require, only to change cavities and other moulds can get different types of pillar candles, following loading material, the whole process will be completed from pressing to material returning automatically.

Loading wax powder into hopper, with the pillar candle making machine rotating, wax powder flowing into the cavity,the upper and lower punches press the up and down ends of the cavity at the same time.

The candles pressed out with a center hole inside the candle to allow for the candle wick and pushed to the conveyor belt by the material tamping rod, the process finished.

Wax powder in the cavity, sauce with heating belt, so candle's surface smooth. If the upper punch with carved patterns, the candles pressed out with carved patterns.

The pillar candle making machine is manufactured by the carbon structural steel and adopts the design of box structure. To enhance the strength and prolong the service life of the machine, the major parts receive the strict heat treatment to ensure the durable operation.

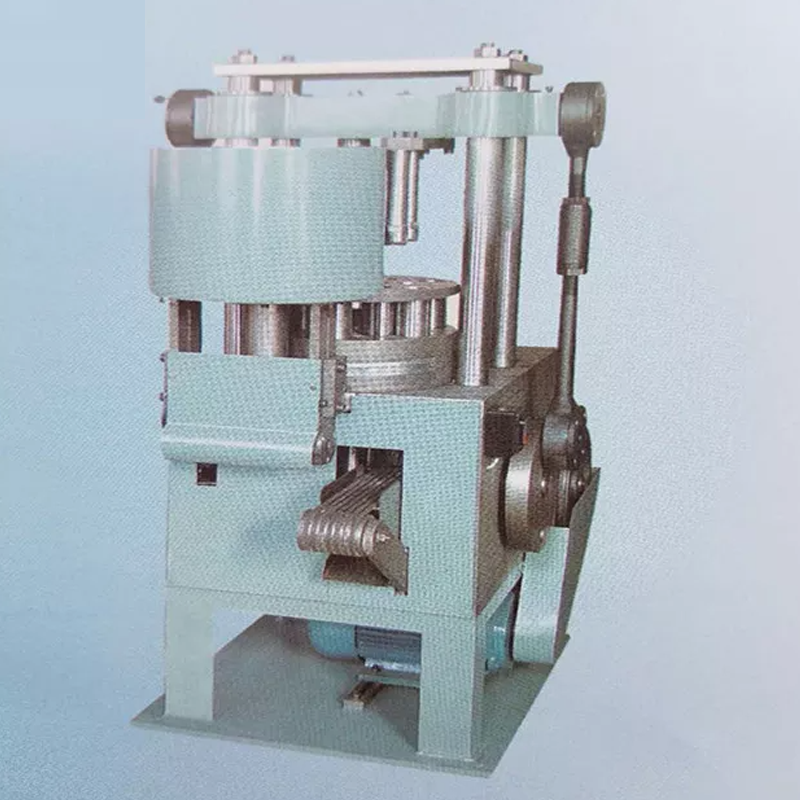

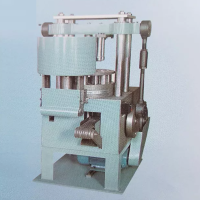

Multi-function 4 - 9 Pillar Candle Machine with reverse pressing function, according to the customer' sreuquire, only to change cavities and other moulds can get different types of pillar candles, following loading material, the whole pupcess will be completed from pressing to material returning automatically.

Working Procedure Loading wax powder into hopper, with the machine rotating, wax powder flowing into the cavity, the upper and lower punches press the up and down ends of the cavity at the same time.

The candles pressed out with a center hole inside the candle to allow for the candle wick and pushed to the conveyor belt by the material tamping rod, the process finished.

Both upper and lower punches have heating section, saucer with heating belt. So candle's surface smooth, if the upper punch with carved patterns, the pillar candles pressed out with carved patterns.

Changing moulds will get different types and sizes of candles, we constantly provide different types of moulds for customer'require, sending me candle samples, we supply moulds to u, also supply candle making machine parts for long-term.It adopts the emergency brake device to allow the emergency brake at any time and under any occasion.

It thus guarantees the safety of candle making machine maintenance, emergency brake and personnel. Changing moulds will get different types and sizes of candles, we constantly provide different types of moulds for customer' s require, sending me candle samples, we supply moulds to u, also supply candle making machine parts for long-term.

According to the customer's require, only to change cavities and other moulds can get different types of pillar candles, following loading material, the whole process will be completed from pressing to material returning automatically.

Loading wax powder into hopper, with the machine rotating, wax powder flowing into the cavity, the upper and lower punches press the up and down ends of the cavity at the same time.

The candles pressed out with a center hole inside the candle to allow for the candle wick and pushed to the conveyor belt by the material tamping rod, the process finished.

Wax powder in the cavity, sauce with heating belt, so candle's surface smooth. If the upper punch with carved patterns, the candles pressed out with carved patterns

The machine is manufactured by the carbon structural steel and adopts the design of box structure. To enhance the strength and prolong the service life of the machine, the major parts receive the strict heat treatment to ensure the durable operation.