50Kg Wax Melting Machine

50kg Wax melting machine uses steam / heating oil system / electric to keep the temperature of liquid wax. According to the needs of customers, we can customize and increase the stirring function,mix liquid wax, color and fragrance uniform.Widely use in candle factories.

- GAOWAX

- China

- 15~30days

- 50 Sets per Month

- Information

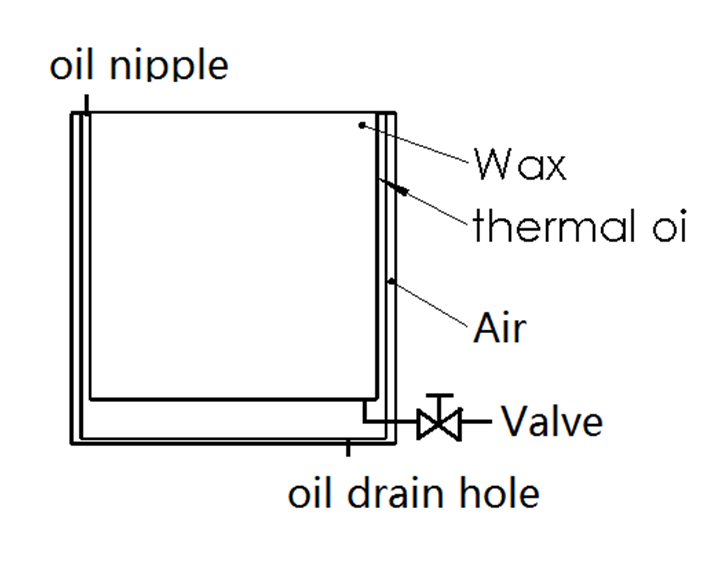

Wax-melting Pot is composed of three layers stainless steel plate, heat conduction layer and insulation layer plate (tank).

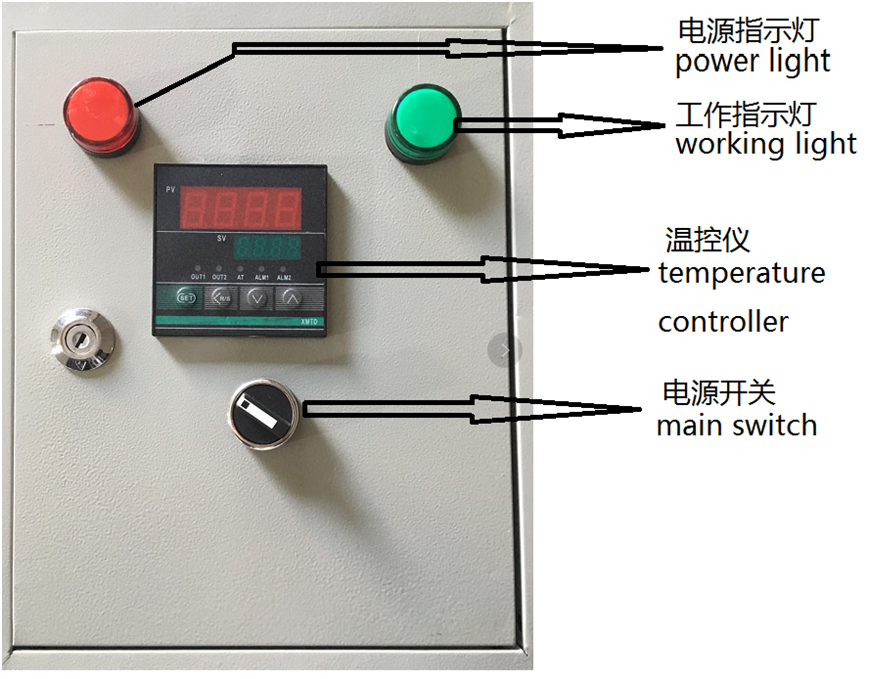

Using the heat conduction oil heating, electric heating tube to heat conduction oil heat melted paraffin wax, wax melting pot is equipped with temperature control instrument,indicator lights, ac contactor and paraffin wax temperature heat transfer rod device, in order to realize the automatic temperature control.

Capacity | Volume | Voltage | Power | Inner Size | Valve size | Packing Size |

25KG | 33L | 220V/380V | 3KW | 35*35CM | 3/4'' | 72*57*59*CM |

50KG | 70L | 220V/380V | 6KW | 45*45CM | 3/4'' | 82*67*69CM |

80KG | 100L | 380V | 6KW | 50*50CM | 3/4'' | 87*71*76CM |

100KG | 130L | 380V | 6KW | 55*55CM | 3/4'' | 92*76*72CM |

150KG | 170L | 380V | 12KW | 60*60CM | 1'' | 97*82*88CM |

150KG | 204L | 380V | 12KW | 54*54*70CM | 1'' | 105*64*84CM |

200KG | 270L | 380V | 12KW | 58*58*80CM | 1'' | 115*70*90CM |

250KG | 324L | 380V | 12KW | 60*60*90CM | 1'' | 125*72*92CM |

300KG | 400L | 380V | 12KW | 64*64*100CM | 1'' | 135*76*98CM |

500KG | 640L | 380V | 28KW | 80*80*100CM | 1'' | 100*130*140CM |

1000KG | 1400L | 380V | 30KW | 100*100*140CM | 1'' | 156*136*110CM |

Wax Melter Foundation drawing:

1.(Inspection before using):

Adding enough conduction oil: this wax melting machine uses electric heat pipe to heat the conduction oil, and then using the heat to melt wax, to achieve the purpose of thermal fast, temperature uniformity, and saving electricity. Because the above of wax melting box cannot be closed, so the conduction oil cannot be added when the machine leaves factory for long distance transportation. Only before using can add conduction oil. The quantity of conduction oil is just added to two-thirds is appropriate, to prevent conduction oil is too filled after heating expansion spillover.

2.(Setting temperature):

The up number on the temperature controller is the actual temperature of the thermal oil. The below number is the set temperature. Press the "set" key and the setting temperature can be adjusted by the upper and lower arrows. When the temperature controller reaches the set temperature, the power supply is automatically cut off and stopped heating. When the temperature is lower than the set temperature, automatically start heating.

3.(Connecting power):

380 v voltage connects three phase four wire. In order to ensure the safe, when connecting the wire, there must be equipped with leakage protector and wax melting machine grounding line.

4.(Inspection):

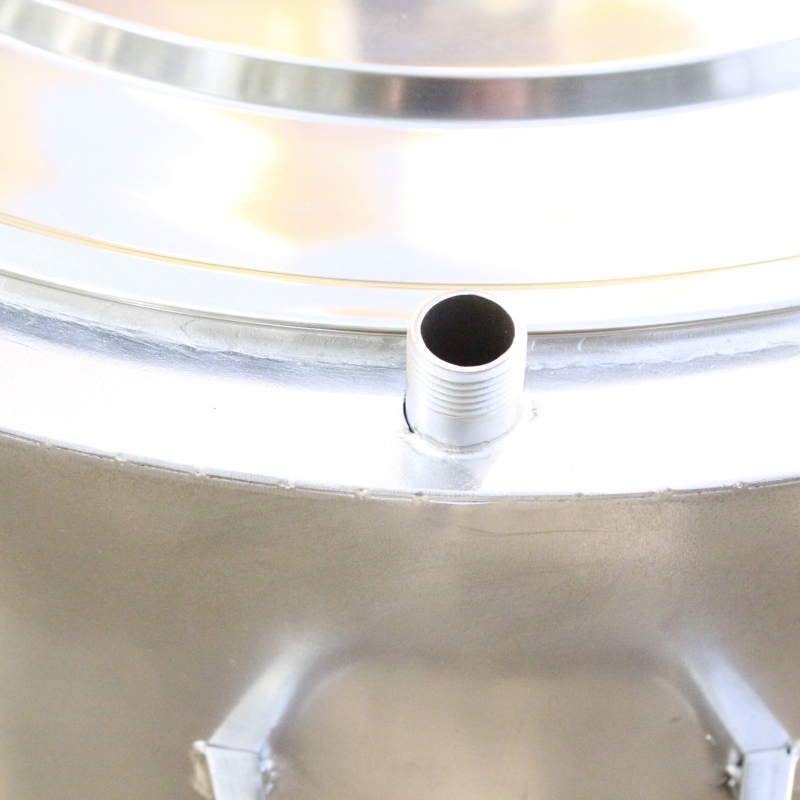

There is conduction oil drain hole at the lower right of Molten wax machine, heating pipe hole at the downside of distribution box. Put conduction oil into the machine to check whether the two holes loose or leak. Make sure the valve is closed before use. Confirm that the dustproof bend has been installed on the oil nipple to prevent dust and other impurities from entering the thermal oil.