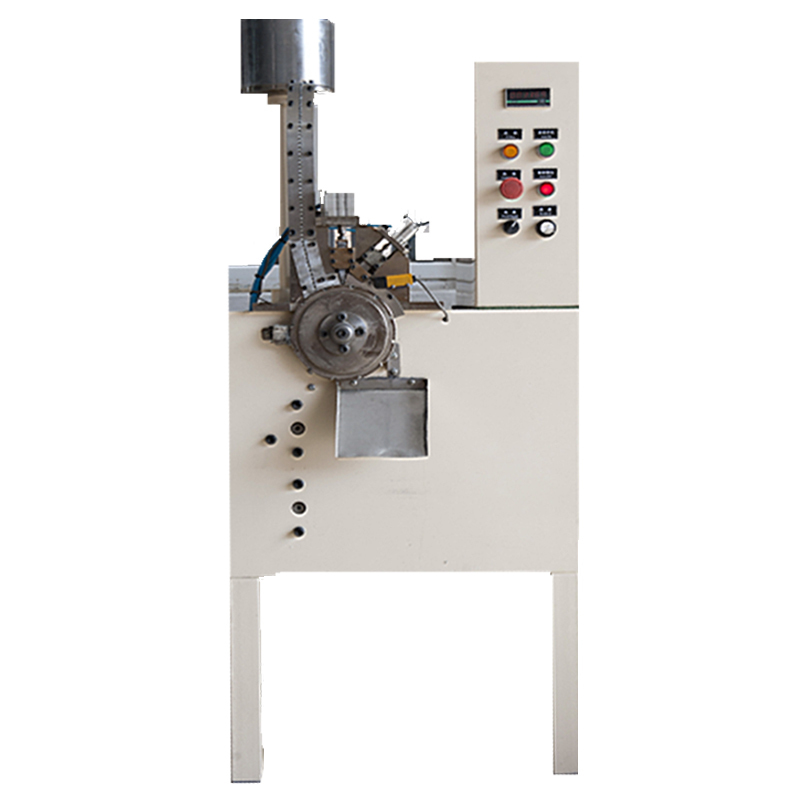

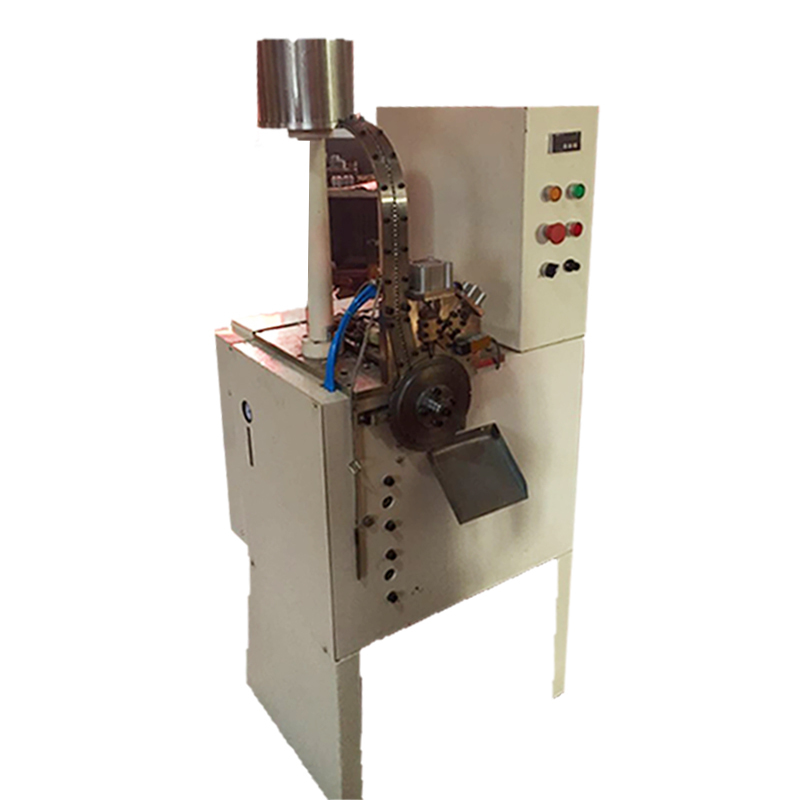

Candle Wick Cutting Machine Pneumatic Power

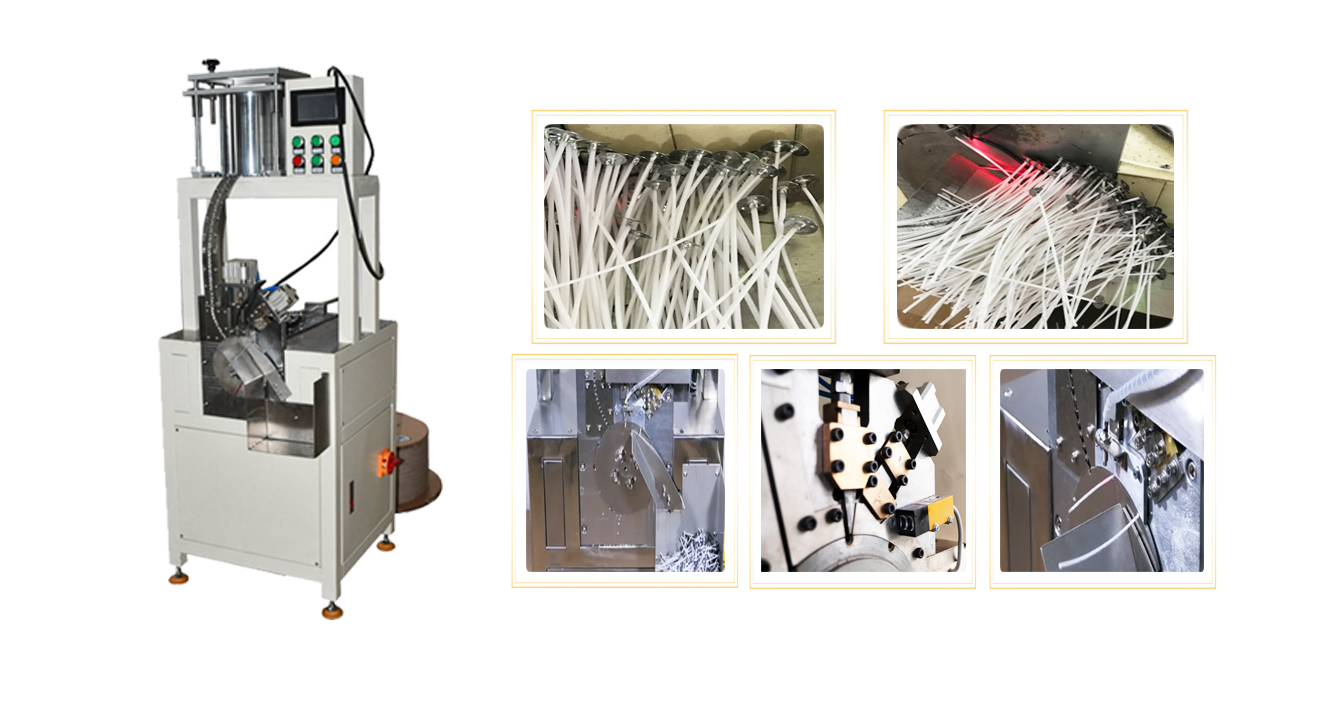

Candle wick cutting machine is used to cut wax coated wick which is made by wick dipping machine into required length and fix wick with sustainer.

Working speed can be controlled, as well as counting output. With monitor function, if no sustainer, wick fold or other issues, it can stop working automatically, this will be convenient for operating, meanwhile save labor and guarantee products' successful rate.

- GAOWAX

- China

- 15~30days

- 50 Sets per Month

- Information

Automatic candle wick cutting machine in the original automaticcandle wick cutting machine on the basis of more perfect improvement.After the improvement, the functions required by the wick clamping machine have been greatly improved through the combination of various related components: wax feeding, wax wire, wire cutting, the whole process is carried out automatically under the electronic control;Especially the cord-cutting length from 10mm-350mm to infinite length, the operator can do any setting on the controller, length error is small.It is suitable for the wax core production of various specifications of cup wax, column wax, tea wax and artistic candle.

Automatic wick cutting machine is a common equipment for candle manufacturing enterprises.

Item | Main technical parameters |

Device name: | Wick cutting machine |

Model: | GW-090 |

Neck height of wax holder: | 3mm-4mm |

Diameter range of wax holder: | 12.5-14mm,other size replacement mold |

Candle wick wire diameter: | 1.5-2.5mm,other diameters to be customized |

Voltage: | 380v (conventional); 220v can be customized |

Candle wick length range: | 10mm-500mm |

Hourly output: | 7,200, adjust the speed according to the line length |

Main motor power: | 0.37KW |

Stirrer power: | 0.025KW |

weight: | 200KG |

Dimensions: | 600*600*1250mm |

Power configuration: | 0.37kw voltage 380v; 220v customized |

Application: | The candle wick and wax tray are clamped together by the machine. |