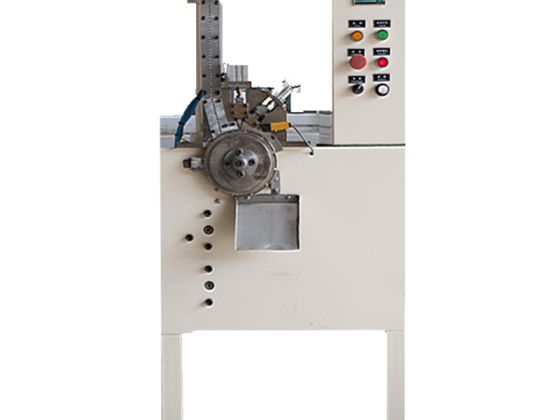

Candle Wick Dipping Machine

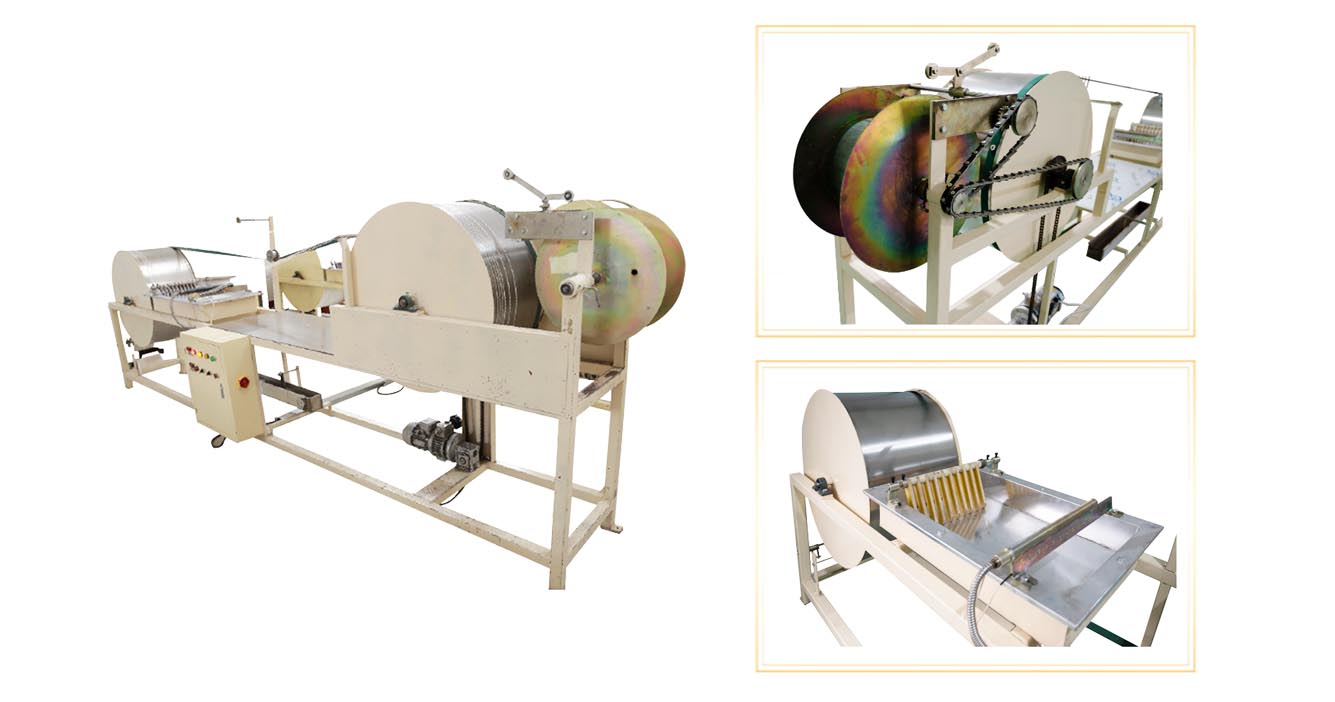

Candle wick dipping machine is used to coat wax on cotton candle wick by different times and then cooling in order to get different diameter wick.

Wax coated wick surface is smooth and round, can be used on wick cutting machine directly.

Candle wick dipping machine has auto temperature controlling function, safety melting. Main parts which touch wax are made of stainless steel, aluminium or with plating, to avoid rusting for touching wax. Main motor is combination of stepless motor and worm reducer, this will be easy for controlling speed.

- GAOWAX

- China

- 15~30days

- 50 Sets per Month

- Information

The candle wick dipping machine is to apply a thin layer of wax around wick. The two wick rolling drums of wick dipping machine are made of stainless steel sheet, which is not only easy to clean, but also corrosion proof. Wax temperature is controlled by thermostat, making the operation safer. The wick is repeatedly led through the molten wax and suitable calibrators until it reaches the desired diameter.

The wick dipping machine is highly productive, and produces 2000 meters of waxed wick per hour. The wick dipping machine is automatic, user friendly, and operator needs no special training.

Power | 4.5KW |

Voltage | 380V/50Hz |

Waxing Speed | 2000m/h |

Diameter of Wick | 1.2-3.0mm |

Gross weight | 300KGS |

Dimension | 420*80*145cm |

Candle wick dipping machine is used to dip cotton wick into liquid wax ,then waxed wick can be used on other machines.

Candle Wick Dipping Machine Features:

The main frame of our machine adopts a combination of stepless speed control and worm speed reducer. It is directly connected to the power box. The aluminous crust makes the whole machine looks more beautiful and dignified. It also has the following characteristics: high-level of speed adjusting, good effect of blowing away heat, running smoothly, low noise, long term of usage, etc.

The automatic temperature controlling function makes the operation much easier. The double safety protection makes the wax melting process safer. The unique stepless speed control makes the adjusting of speed more flexible.

The aluminous melting basin has a nice capacity of conducting heat, which makes the melting process faster.

The accessories that connected to the liquid wax are all made of stainless steel or aluminum, which can prevent them from reacting with the paraffin and be rusted.

Also it is easier to clean up. The automatic moving lead shelf can make the wick more symmetrical.