Wax Powder Making Machine Milling Drum

Wax powder making machine milling drum can make liquid wax into powder wax.And the material we use is stainless steel ,so can be used for producing paraffin ,palm wax and stearic acid. Milling drum can be used by areas with different temperature, taking less space and easy operating are its characteristics.

- GAOWAX

- China

- 15~30days

- 50 Sets per Month

- Information

Wax powder making machine milling drum is used to make liquid wax like paraffin wax, palm wax, stearic acid of candle material into powder wax for pressing candle. It is made up of drum, wax temperature keeping tank, electrical control box and so on, stainless steel is used as main material, so it is anti-corrosion.

Fill heating oil to the interlayer of wax temperature keeping tank in order to keep liquid wax. Cycle cold water should connect to drum.

In a room which the temperature is under 25℃, liquid wax are sprayed out through nozzles on spraying bars, during dropping and when falling on the drum surface, liquid wax cool down and freeze. When drum moves to the blade, powder wax is scrapped off. Then powder wax will be transferred inside the drum for further cooling through vibrator and boards, after fully cooling, powder wax drop into powder wax tank.

Wax powder making machine milling drum can be used by areas with different temperature, taking less space and easy operating are its characteristics.

There are two output option, one is 400-500kg/hour, the other one is 800-1000kg/hour.Wax powder making machine milling drum needs to work with chiller unit and temperature keeping device.

Output | 500kg/h |

Electric heating power | 12KW (6pcs preheating pipes) |

Cooling water consumption | 15m3/h |

Pressure of compressed air | 0.6-0.8Mpa |

Dimension (L×W×H) | 3400×4080×2600mm |

Weight | 2980kg |

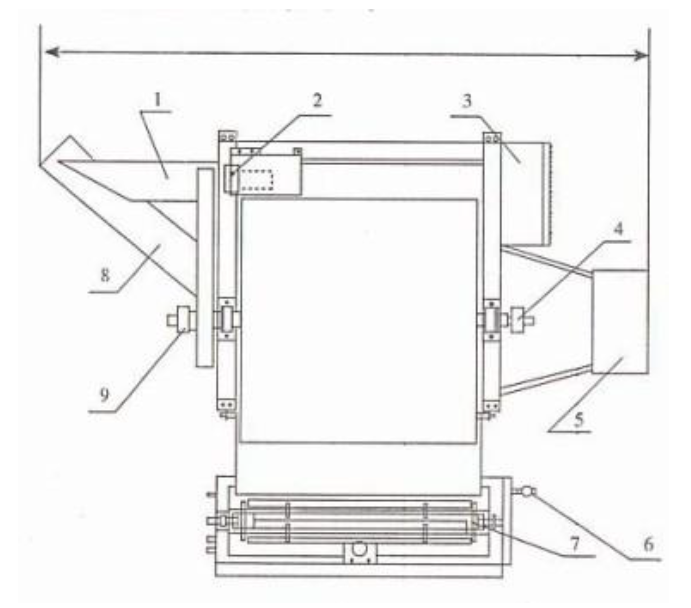

Schematic Diagram of Equipment Structure:

1. Big Vibrating Trough

2. Reducer

3. Electrical Appliance Control

4. Rotary Joint of Inlet Pipe

5. Storage Tank

6. Steam Heating Electromagnetic Valve

7. Candle Liquid Nozzle

8. Small Vibrating Trough

9. Rotary Joint of Outlet Pipe

Wax Powder Milling Drum Maintenance:

1 .When installing the equipment, it should possess the fine grounding device and it should frequently examine the grounding to avoid the electric shock accidence.

2. When shutting down the equipment, open the valve in both ends of the nozzle and discharge the remained candle liquid.

3. When shutting down the equipment, it should timely examine the fastening screw of the big and small vibrating trough whether it is loosened. If it is loosened, it should timely screw it up to avoid the failure.

4. It should regularly examine the height of the heating oil level to avoid impacts on the heating effect.

5. After 50 to 60 hours of the first running, the reducer should replace the lubricating oil and then it should be done once per three months. In the meanwhile, it should and clean the candle powder on the wind wheel that back of the motor.

6. When replacing the candle liquid trough electric heater, it should firstly open the oil outlet valve and discharge the heating oil. After replacing it, it should close the oil outlet valve and inject the heating oil newly.

7. The operation site should be dust-free, corrosive gas and liquid-free and floating mental particles-free and electromagnetic interference-free, far away from the interference source to avoid the impacts on the normal operation of the transducer in the electrical appliance control.